Key Difference – Rayon vs Nylon

Although rayon and nylon are two artificially manufactured fibers, there are many differences between them. Rayon possesses many properties of natural fibers since it is a semi-synthetic fiber. Nylon is a synthetic fiber and has properties that are completely different from natural fibers. The key difference between rayon and nylon is their resistance to wrinkles and tears. Rayon is more prone to wrinkles and tears whereas nylon is resistant to wrinkles and tears and require low maintenance.

What is Rayon?

Rayon is a regenerated cellulose fiber. It is considered as a semi-synthetic (neither natural nor synthetic) fiber that is made from wood pulp, a natural raw material based on semi-cellulose. Although rayon is a manufactured fiber, it shares many similarities with natural fabrics such as cotton and linen.

Rayon is soft, breathable, comfortable and moisture absorbent. This moisture absorbance and softness of the fabric make it ideal for summer wear. This fabric also drapes well. However, rayon fiber is also prone to wrinkles, creases and tears just like natural fibers. This fabric is also blended with other materials to achieve different properties. Rising prices in cotton have increased the demand for rayon since rayon is being used as a substitute for cotton.

It is also important to note that various characteristics and properties of rayon depend on its many factors such as processing and additives. There are four major types of rayon fabrics known as regular rayon, high wet modulus rayon, high tenacity modulus rayon and Cuprammonium rayon.

What is Nylon?

Nylon is not a natural fiber; it is a synthetic fiber that is made from chemical by-products of petroleum, coal, and agricultural products. Nylon is often referred to as a polymer and the material used to produce nylon is known as polyamides. It was first produced by Wallace Carothers at the DuPont Experimental Station. Nylon became popular during the Second World War due to the shortage of natural fabrics such as silk. It was used to manufacture parachutes, tires, tents, ponchos, ropes, and other military supplies.

Nylon fabrics have a low absorbency rate, making them ideal for the manufacture of stockings, swimwear, and athletic wear. Nylon is a very popular fabric today due to its low cost, durability, and low maintenance. It is also resistant to heat and tears. This fabric also resists stains and maintain its shape after being washed.

What is the difference between Rayon and Nylon?

Type of Fiber:

Rayon: Rayon is a semi-synthetic fiber.

Nylon: Nylon is a synthetic fiber.

Source Material:

Rayon: Rayon is made from wood pulp.

Nylon: Nylon is made from chemical by-products of petroleum, coal, and agricultural products.

Uses:

Rayon: Rayon is used for blouses, jackets, sportswear, dresses, sheets, blankets, curtains, etc.

Nylon: Nylon is used to make stockings, swimwear, sportswear, tents, tires, parachutes, etc.

Wrinkles and Creases:

Rayon: Rayon tends to form wrinkles and creases easily.

Nylon: Nylon is resistant to wrinkles and tears.

Moisture Absorbency:

Rayon: Rayon has a high moisture absorbency rate.

Nylon: Nylon has a low moisture absorbency rate.

Image Courtesy:

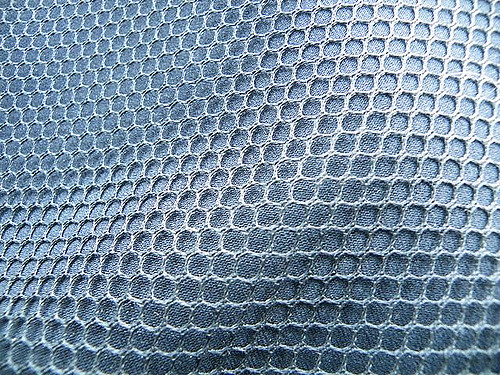

“Nylon Texture” by Jim R Rogers (CC BY-SA 2.0) via Flickr

“Two and a half yards of green rayon” by Quinn Dombrowski (CC BY-SA 2.0) via Flickr

ncG1vNJzZmivp6x7pbXFn5yrnZ6YsqOx07CcnqZemLyue8OinZ%2Bdopq7pLGMm5ytr5Wau26%2BwLKmp2WRo7FuwtJmpbKkn6N8